By Maegan Burkhart

The results are in, and it’s clear customers care more than ever about shipment delivery times:

- 43% of U.S. consumers expect companies to have “much faster” delivery times in 2019

- 42% of online shoppers abandon their carts due to long delivery times

- 75% of shoppers believe proactive communication regarding shipments is important and 38% expect to be notified immediately if there’s an issue

Statistics reveal that 43% of U.S. consumers anticipate companies to achieve “much faster” delivery times in 2019. Additionally, a substantial 42% of online shoppers opt to abandon their shopping carts due to extended delivery times. Furthermore, a staggering 75% of shoppers emphasize the significance of proactive communication concerning shipments, with 38% expecting immediate notification in the event of any issues.

The critical link between meeting delivery expectations and ensuring customer satisfaction lies in the on-time dispatch of goods from the manufacturer’s facility. However, attaining accurate information on lead times, production status, and product quality becomes particularly challenging when dealing with overseas suppliers. Virtually every importer has encountered setbacks in production and shipment schedules with their suppliers at some point.

Given these challenges, it becomes crucial for importers to establish robust mechanisms that guarantee suppliers adhere to production timelines and dispatch goods punctually. In this context, here are three effective methods that every importer can implement to proactively prevent shipment delays with their overseas suppliers.

1. Ensure quality before mass production

The first step to preventing production and shipment delays is to work with trustworthy and honest suppliers from the start. But that’s often easier said than done.

How can you ensure your suppliers will stay on track for production without having worked with them first? While there’s no substitute for actual experience working with suppliers, there are a few steps you can take to vet suppliers before placing an order.

Evaluate your supplier’s processes with an ISO 9001 quality audit

Not all importers can visit their supplier’s facility in person before placing an order. And even if you can visit, you might not know how to effectively evaluate production processes. For instance, if you visit a supplier presenting itself as a furniture factory, you can easily confirm whether that supplier is actually just a buying office. But what about issues with a supplier’s quality records, production schedules, and other more sophisticated processes? These issues can be harder for the average importer to identify during a brief visit.

That’s where a third-party quality audit can help. Most quality audit frameworks are based on the ISO 9001, an international standard for quality management systems. Vetting your potential suppliers against this standard before production begins can help you avoid disorganized suppliers who are prone to unpredictable production delays.

Some red flags a quality audit can help reveal include:

- Insufficient in-line production quality controls to prevent and identify quality issues before shipping

- Insufficient production capacity for your order, suggesting they might be outsourcing all or part of your order to sub-suppliers

- No supplier risk assessment system to prevent the shortage of key materials

- Lacking a detailed production schedule that includes production capacity, orders, stock, product type, and production lead times

- No contingency plans to satisfy customer requirements in the event of an emergency, such as utility interruptions, labor shortages, key equipment failures, or field returns

Establish a “golden sample”

Another key part of the vetting and negotiation stage is to request a production sample from your supplier.

Identifying product defects at the end of production almost always leads to shipment delays as you wait for your supplier to fix and rework defective units (related: How Experienced Importers Limit Product Defects in 3 Stages [eBook]).

Reviewing production samples helps you identify any defects or other quality issues before production begins. This lets you address issues before they affect a high percentage of the mass-produced units.

Provide your supplier with all relevant product specifications, drawings, and quality requirements when requesting the sample, perhaps in one consolidated QC checklist. Then you or a third-party inspector can review the sample in comparison to your requirements and identify any issues with the sample.

You might have to go through a few reviews to reach a sample that matches your requirements 100 percent. This perfect sample is known as your “golden sample” or “approved sample.”

But you don’t want to let any unacceptable quality issues slide in favor of moving forward with mass production faster. It pays to invest time in preventing issues at the beginning of production, rather than trying to address mistakes later. If you skip the vital step of establishing an approved sample, then there isn’t much hope for your entire order.

2. Inspect your order throughout production

Many importers know the value of pre-shipment inspections to verify product quality once an order is complete. But did you know you can inspect earlier in production? You don’t have to wait around for your order to be finished to check product quality.

There are three common quality control inspections importers can conduct throughout production:

- Pre-production inspection, or incoming inspection: Inspection of raw materials or components before production begins

- During production (DUPRO) inspection: Inspection of finished production units when 15 to 80 percent of the order is complete

- Pre-shipment inspection, or random final inspection: Inspection of finished production units when 80 percent or more of the order complete

These quality control inspections can help you prevent three common delays:

Product rework delays

Many quality issues come from a common source. A fabric issue with your garments will likely affect all garments made with that fabric, for instance. A faulty electronic component will affect all units which contain that component.

Inspecting earlier in production allows you to identify these issues and correct them before they affect the entire order. By identifying quality issues earlier in production, you can avoid shipment delays and your supplier racing to correct defective units or produce replacement units.

Customs delays

Your goods don’t just need to meet your and your customers’ requirements– they need to meet legal requirements too. If they do not, your shipment could be delayed as customs officials hold or deny your shipment entry into your target market.

U.S. Customs and Border Protection doesn’t reveal how it chooses which shipments to inspect. But pre-shipment inspection can help your orders meet customs requirements before shipment by ensuring that your supplier:

- Label each package with the proper marks and numbers on your invoice for easy reference

- Marks your goods with the country of origin to comply with country-of-origin marking requirements

- Packages your goods in a uniform manner, ideally with only one kind of product in each carton, for easy inspection

Importers rarely expect they’ll face a customs inspection and most are surprised when their shipment is chosen. Inspecting your goods and packaging to ensure your shipments meet your market’s regulations will help you prepare for customs inspections and avoid any further delays.

Delays at your retailer’s warehouse

Just when you think your products are on their way to their end destination, you get a notice from your retailer: “This shipment has been refused at our warehouse…”

Retailers typically have their own standards you must comply with in order to sell through their platform or retail network. Shipping non-compliant goods to your retailers can cause processing delays, as well as fines and penalties.

Pre-shipment inspection can help you verify:

- Amazon FBA shipment labels and barcodes

- Product quality, to ensure compliance with your retailer’s order defect rates

- Box dimensions and weight, especially relevant for e-commerce fulfillment

- Proper and protective packaging, to prevent damage during shipment

Amazon “prep centers” have popped up in recent years as an option to check and prep a shipment for Amazon’s warehouses. These prep centers will typically repackage products, affix labels, and ship products to Amazon after inspection.

But it’s often too late to fix any serious quality issues at the prep center, aside from minor packaging issues. Inspecting the shipment at your supplier’s facility instead will allow you to fix any serious quality issues before they lead to any delays at your retailer’s warehouse.

3. Monitor production to improve lead times

Inspections during production and pre-shipment are suitable for most importers who just want a snapshot of order quality once or twice before shipment. But you might need broader insight, especially if you’ve been experiencing prolonged production delays.

Production monitoring is a process in which an inspector is stationed at your supplier’s facility daily, or almost daily, over an extended period of time. The inspector will observe production and inspect goods as they come off the production line in real time.

The main value of hiring a third party to monitor production is their independence from the factory. They tend to be more objective than the factory’s own QC team because they’re not associated with the supplier.

Chinese factories often hesitate to be fully transparent with buyers regarding production status and lead times. They might withhold information or provide inaccurate information to buyers to avoid conflict.

Indirect and high-context communication is much more common in China and elsewhere in Asia than in Western cultures. A couple of cultural norms in China often lead to poor communication regarding production status and lead times:

- “Culture of yes”– Your supplier might just tell you what they think you want to hear to avoid conflict. For example, they may tell you there’s no problem with your required shipping deadline, even when they know they can’t meet it.

- “Saving face”– Your supplier might hesitate to ask for clarification or more time out of fear of appearing incompetent. For example, they’re more likely to assume any specifications that you don’t explicitly provide, instead of directly asking you for them.

Through production monitoring, a third party can provide you with an unfiltered look at actual production status, as well as product quality.

Gain objective information on production status

Production monitoring obviously comes at a higher cost than a pre-shipment inspection, as you’ll need to pay for an inspector to be on site for several days in a row. But with the extra time on site, you’ll get greater insight into production status, which can be invaluable in managing expectations with your customers.

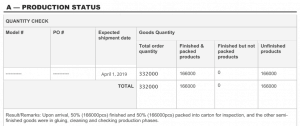

Production monitoring can help you assess the number of:

- Finished and packaged products

- Finished but not yet packaged products

- Unfinished products

- Workers on duty

Your inspector should report to you after each day at the factory with information on production status, as in the table below:

The inspector can also calculate the factory’s first-pass rate or ratio during production monitoring. This rate measures the percentage of the products that pass all quality requirements without rework, compared to all products manufactured during a period.

A high first-pass ratio indicates a factory that can more likely meet your shipping deadlines, as workers can finish your order without much necessary rework.

For example, the below production monitoring report shows that this factory has a first-pass rate of 95.2 percent, meaning about 95 percent of goods passed inspection:

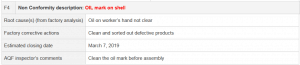

The exact inspection scope of production monitoring can often be tailored to your specific needs. Production monitoring could involve quality control checks such as:

- Item measurement, especially for critical components with low tolerances

- On-site tests for function, performance, or safety

- Status check of corrective actions on previously identified nonconformances, like the below example:

Not all importers need to monitor production in this fashion. But you might find it helpful for new suppliers, new products, or peak seasons when production lead times are more important and quality issues are more likely to occur.

Conclusion

Managing production lead times and shipment delays often goes hand in hand with managing product quality (related: The Importer’s Guide to Managing Product Quality with AQL [eBook]). Managing expectations with your suppliers will help them meet your standards and prevent miscommunication, misunderstandings, and delays.

You may feel like you’re increasing your production lead times, rather than reducing shipment delays, by adding these extra steps. But in reality, clarifying expectations up front, performing inspections and monitoring production almost always help importers reduce shipment delays in the long term.

You’ll be in a much better position to adjust and prepare your supply chain for delays if you’re aware of them in advance. And you won’t have to face your customers’ wrath when you make last-minute changes to their delivery schedules.

Maegan Burkhart is a Content Specialist at Asia Quality Focus (AQF), a Western-owned, third-party QC firm headquartered in Shenzhen, China. AQF helps importers improve their product quality and manufacturing experience by offering tailored product inspections, supplier evaluations and lab testing in Asia through their online platform.