In today’s trade environment, there’s a lot of talk about producing goods outside of China. But will shifting production help or hurt your business?

Nathan Resnick, CEO and Founder of Sourcify, and Tal Kohn, Freight Marketing Pricing Analyst at Freightos, teamed up to give you the information you need in the first webinar of our Three Weeks of Peak Series.

Read on to decide if sourcing outside of China is right for you or check out the full webinar video below.

Need a freight quote outside (or inside) of China?

Advantages and Disadvantages of Working Outside of China

One of the major advantages to working outside of China is that production costs can be dramatically lower. For example, in China, labor costs have risen over the past 15- 20 years, whereas in countries like Vietnam, India, and Bangladesh, the cost of labor has remained low. Another advantage is if you choose the right country for your product, it can decrease lead time and increase quality. A third advantage is that producing in other developing countries can help U.S. brands avoid Chinese tariffs.

However, there are also disadvantages to working outside of China.

The main challenge is that the raw material sources outside of China are not as broad as in China. Another is that infrastructure outside of China often lags, which means lead times can become a challenge and production delays can be more common.

Saving on Production Costs

The following graph shows factory salaries in China and outside of China:

As you can see, wages are much higher in China. It’s important to note that this graph shows average estimates, with real salaries dependent on the location of the specific factory. For example, closer to bigger cities like Guangdong or Shenzhen, labor rates will be much higher, whereas in more remote areas, labor rates are going to go down. Take these rates into account when planning your production costs.

Another important piece to saving on production is analyzing your actual component costs. Typically a contract manufacturer will give you all-in costs, but asking for a breakdown will help you understand where you can save.

Here’s an example: let’s say you’re producing a watch. You want to understand: what’s the cost of the watch hands, the watch strap, and the watch movement– that is, the unit costs behind each component? But also understand the labor rates: how long does it actually take to assemble a watch? What does that translate into from a labor cost standpoint?

Knowing these details can help you plan strategically.

What is the Best Country to Choose for Manufacturing?

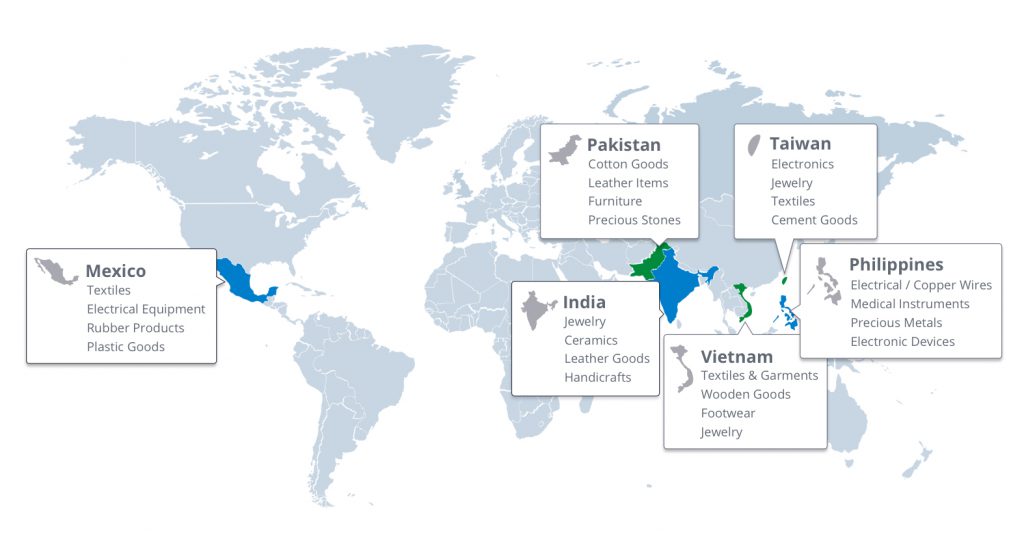

Every country has its own specialties. Check this map to see which country is best for producing your products:

One note on shipping from the Phillippines: in the Philippines, there is a growing sector of free economic zones, which were set up by the government to boost labor and employment rates. So although raw material sources in the Philippines are limited, you can choose to have your factory in the Philippines, import materials from other parts of Asia, manufacture in a free economic zone, and then export it for free from the Philippines as well.

Key Questions to Ask When Considering Sourcing Outside of China

Where do the raw resources come from?

You’ll want to choose a country that is able to source your product.

What are the capacity limitations?

For very large companies, note that many large factories fill their yearly capacity quickly, so these get booked well in advance.

For most e-commerce companies, primarily working with small and medium-sized factories that are looking to grow, you’ll have the most success by getting on the same page with your supplier about sales forecasting. Factories outside of China are growing very fast, but they don’t have the experience of a factory in China that has been manufacturing for 20 years, so clear communication and goal-setting are key.

How does exporting from this country actually work?

Exporting products from the Philippines or Vietnam can be different from exporting from China. Talk to your customs broker about duty rates, which are calculated based on the country of origin.

One note of caution: some Chinese factories are selling new facilities in Vietnam or Malaysia or the Philippines, but many times these facilities outside of China might not provide enough value-add to the goods. They may simply be repackaging products that were already made in China. For your product to actually change country of origin, there needs to be a significant value-add to the product in that country of origin.

What are the product regulations?

It’s important to know your product’s regulations, especially when there might be FDA requirements.

For example, one product that people often overlook is sunglasses. To import sunglasses to the U.S., factories need to be FDA approved because sunglasses are technically a medical device. So as you expand to new product lines and work with new factories, make sure that they have the right certificates so your products won’t get stuck at customs.

Avoiding Supply Chain Issues

When you’re considering shifting supply chains and moving production, make sure to avoid supply chain problems that can arise. Here are some steps you can take:

- Work with a local sourcing team such as Sourcify to make sure you have price visibility and get multiple price quotes

- Use multiple factories so that if something goes wrong with your factory you don’t have to scramble to maintain your inventory

- Consult a customs officer or broker to understand what duties you’ll owe when importing your products.

- Understand your costs across your entire supply chain. Unit costs, freight rates, duty costs– these are all important pieces to understanding how much it will cost you to actually get your product landed to your customer.

- Map out your shipping options to make sure you’re getting the best freight prices and transit times

Origin Ports, Transit Times, and Pricing Outside of China

If you choose to source from Southeast Asian countries outside of China, there are a few major ports to familiarize yourself with.

Major Ports for Export in Southeast Asia

Pakistan Ports

In Pakistan, there are two main places where a lot of manufacturing takes place: Lahore in the north and Karachi in the south. Now, Karachi is the one that’s right by the ocean, so anything made up north usually ends up there to be sent out internationally.

This geography tidbit is pretty important for making sure things run smoothly. It means that if you’re working with suppliers in the north, you’ll likely need to coordinate with the central export hub in Karachi to get your stuff shipped out efficiently. Understanding this can make communication smoother and help avoid delays in getting your products to customers on time.

Vietnam Ports

Vietnam is a country that stretches out like a long, thin strip. Up in the north, close to the capital Hanoi, you’ll find Haiphong. In the central part, there’s a city called Da Nang. Down in the south, near Ho Chi Minh City, there are various terminals for shipping, and one of the main ones is Vung Tau.

Understanding this geographical layout is essential if you’re working with suppliers in different parts of Vietnam. It helps you navigate the logistics of getting your products from where they’re made to the right shipping terminals for international transport.

Taiwan Ports

Taiwan has a bit of a different shape, like a leaf, and it’s got some key spots for shipping. Up in the north, there’s the main seaport called Keelung. Moving towards the middle, you’ll find Taichung, and down in the south is the bustling city of Kaohsiung.

Each of these places plays a specific role in getting things in and out of Taiwan. Keelung, up north, is like the entry gate for a lot of goods. In the middle, Taichung does its part, and down in Kaohsiung, there’s a major hub for shipments.

So, if you’re working with suppliers in different parts of Taiwan, knowing these locations is like having a map for your shipping journey. It helps you figure out the best routes to get your products from where they start to where they need to go, whether that’s by land or by sea. Understanding these spots is key to making sure everything flows smoothly in your supply chain.

The Philippines Ports

The Philippines is made up of a bunch of islands, and when it comes to shipping, there are some key spots to keep in mind. Up in the north, you’ve got the ports of Manila and Subic Bay, which are a bit to the west of Manila.

Moving towards the middle, there’s Cebu, an important hub for trade and shipping. Down in the south, you’ll find the Port of General Santos, another significant location for moving goods in and out of the country.

Knowing these key ports helps you navigate the geography of the Philippines when you’re working with suppliers in different areas. It’s like having checkpoints on a map to make sure your products can smoothly travel from where they’re made to where they need to be shipped out internationally. Understanding these locations is like having a handy guide for a successful shipping journey in the Philippines.

India Ports

India, a vast and diverse country, has several key ports that play crucial roles in its trade and shipping network. In the north-central part, New Delhi stands as a major hub, facilitating the movement of goods. Towards the northeast, Kolkata serves as another significant port, contributing to the regional trade dynamics.

Heading southeast, the port of Chennai plays a pivotal role, acting as a gateway for trade activities in that part of the country. In the southwest, Mumbai and its nearby port, Nhava Sheva, form a bustling hub for international shipments. Further to the west, Mundra serves as a prominent port, contributing to the western trade routes.

Understanding the locations of these ports is essential for businesses working with suppliers in various regions of India. It’s like having a map to guide your products from manufacturing hubs to the right ports for smooth and efficient international shipping. Each port plays a unique role, and knowing their locations helps ensure a well-coordinated and successful supply chain in India.

Shipping from Outside China: Transit Times

Here’s what you can expect from the transit times compared with what you might experience when shipping from China. This information is for LCL ocean shipments:

This chart shows how many days it takes to get to Los Angeles, Houston, and New York. The countries near China, such as Vietnam, Taiwan, and the Philippines, have similar transit times to China. With Taiwan, since it’s a little bit further to the east, you may gain a day, whereas Pakistan and India have longer times not only because they are further away, but also because oftentimes there’s transloading or stops along the way towards the United States that increase transit time.

India is different from the other countries because whereas from other countries, goods typically move east over the Pacific Ocean to the west coast of the United States, India, because of its geographic location and different production sites, can send freight both eastbound coming from the east of India, and westbound to reach the east coast of the U.S.

That means that whereas for every other country, transit times increase as you move from west to east U.S., India has the longest transit time to Houston and shorter times to both Los Angeles and New York.

Shipping from Outside China: Pricing

Here is the kind of pricing that you might expect for a 1.5 CBM, 300-kilogram shipment with port-to-port costs:

Once again, going from west to the east mostly increases prices, except for India where shipping to Houston is on average the most expensive.